Our founders have careers experimenting with, crafting, and refining a Strategic Product Development Methodology that uncovers and nurtures a culture of innovation. By focusing on understanding the human experience we create products that truly enhance people’s life’s and capture market opportunities. Outlined below chronicles steps and timeline in the creation of our innovative products.

1 : Explore

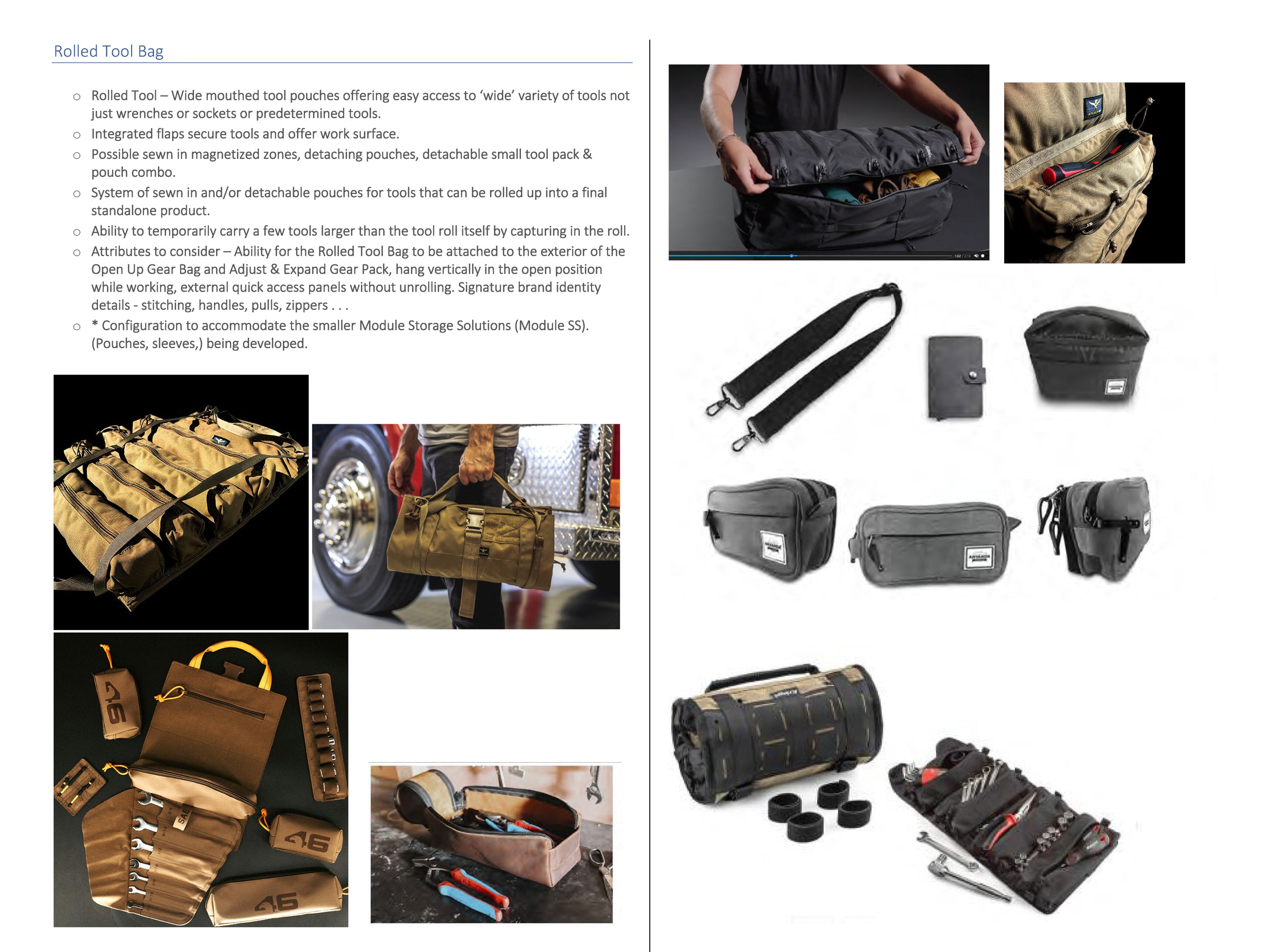

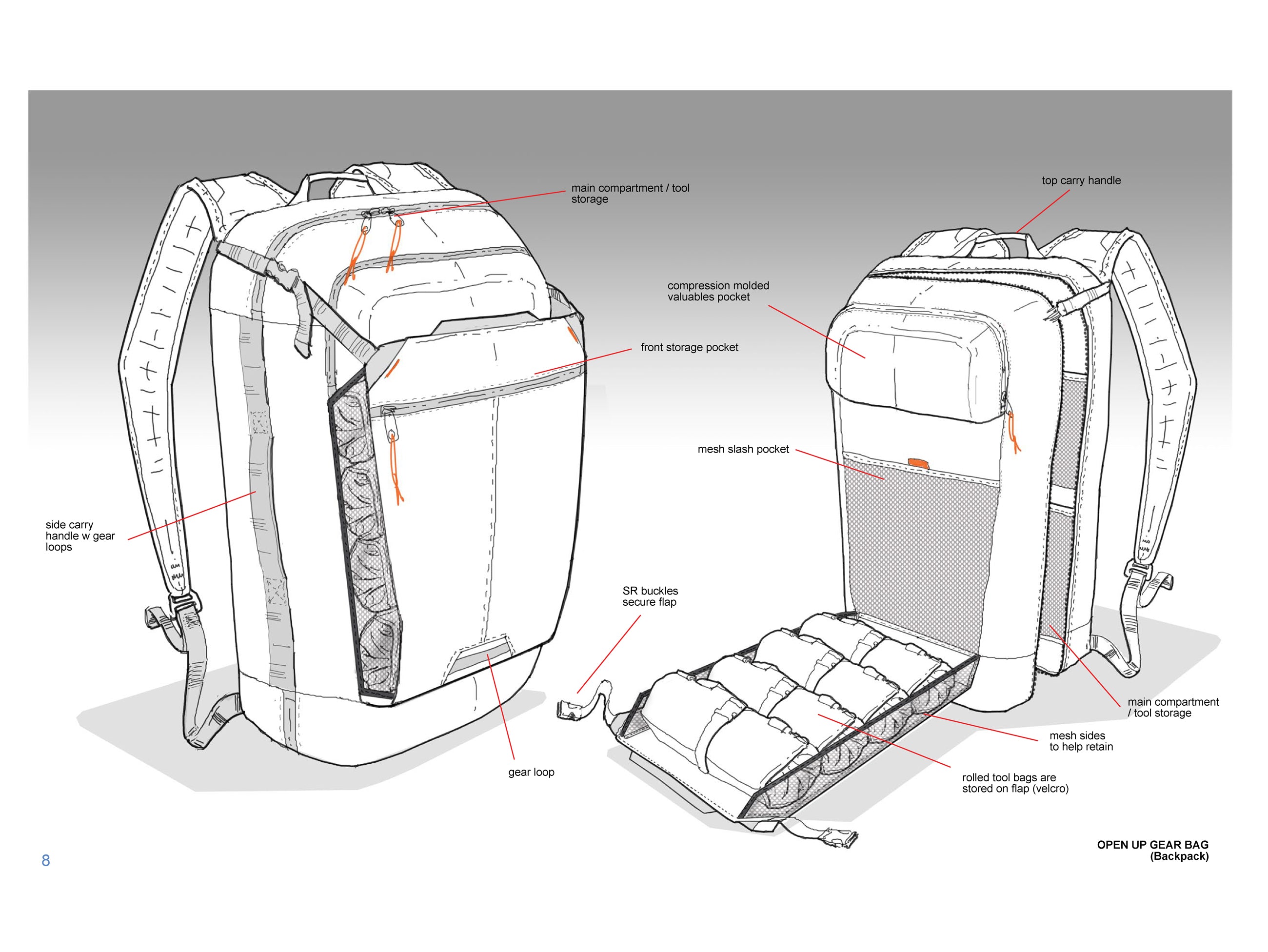

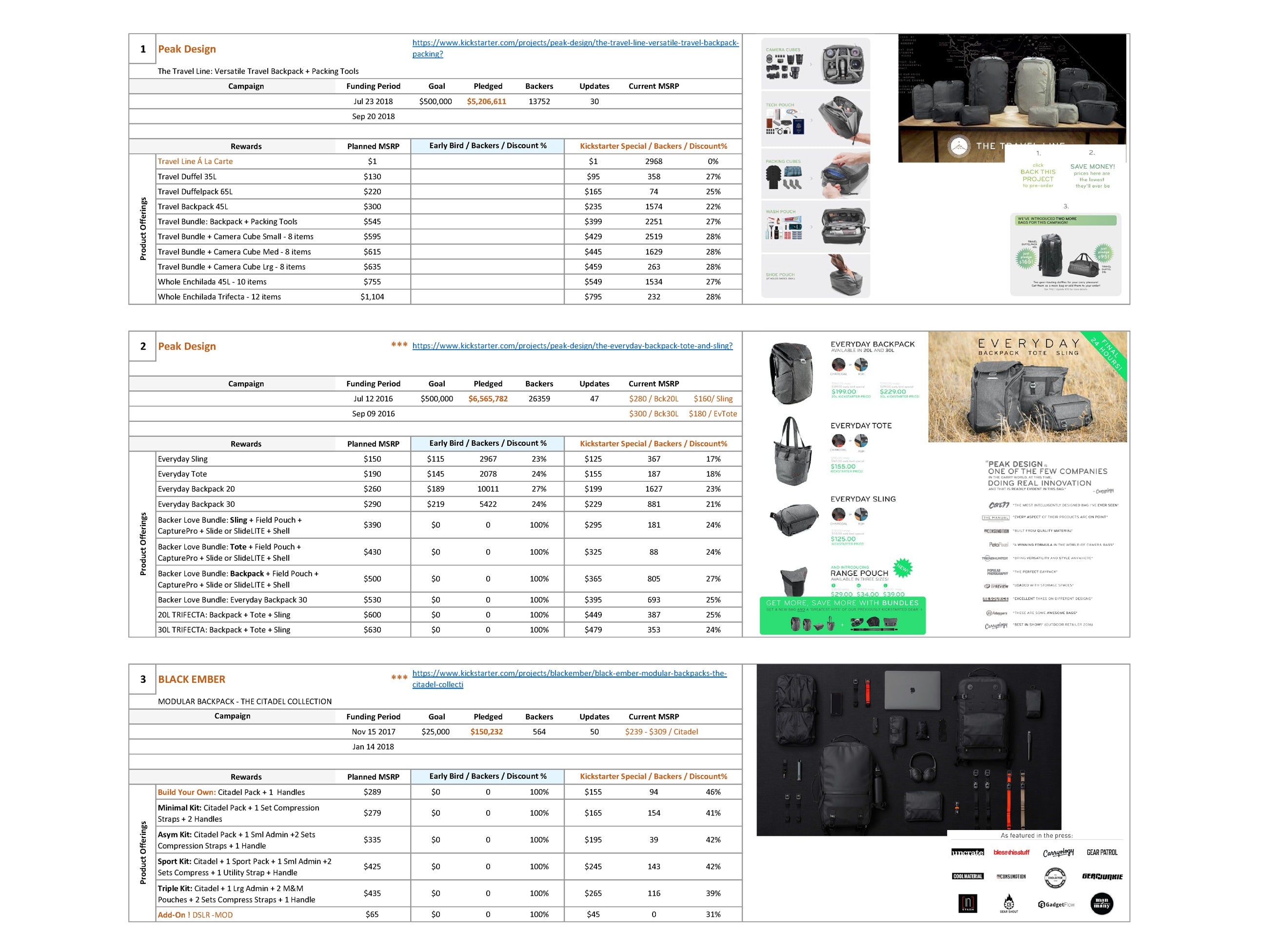

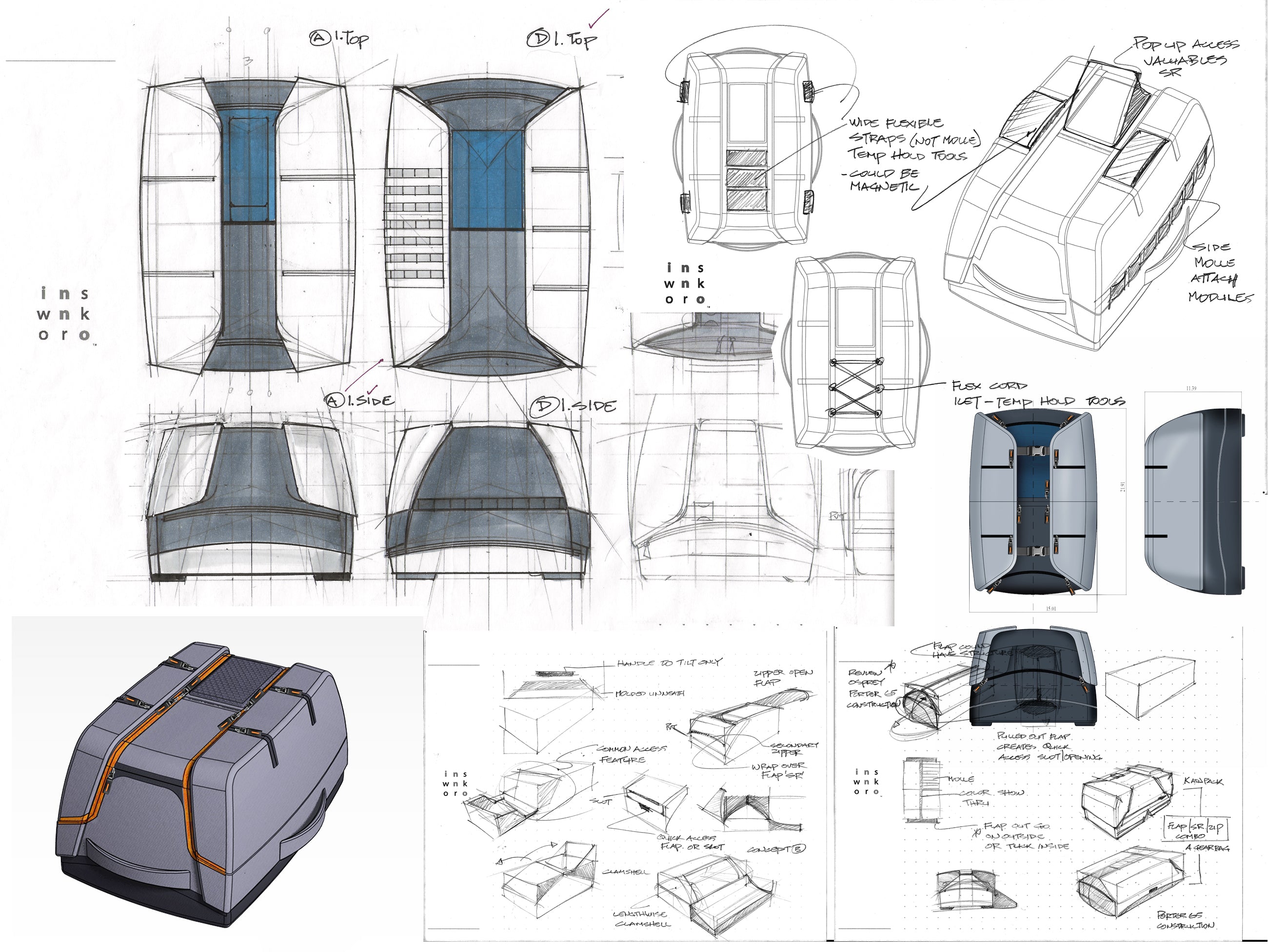

Start of our first discussions between CoFounders to discuss potential product categories to address for NewCo - objectives, functional parameters, user needs, competitive products & feature analysis to establish product attributes and a Platform for study. Investigate multiple concept designs addressing the objectives, goals, constraints, user orientation, market needs, to evaluate aesthetic, compartmentalization, and organization of tools.

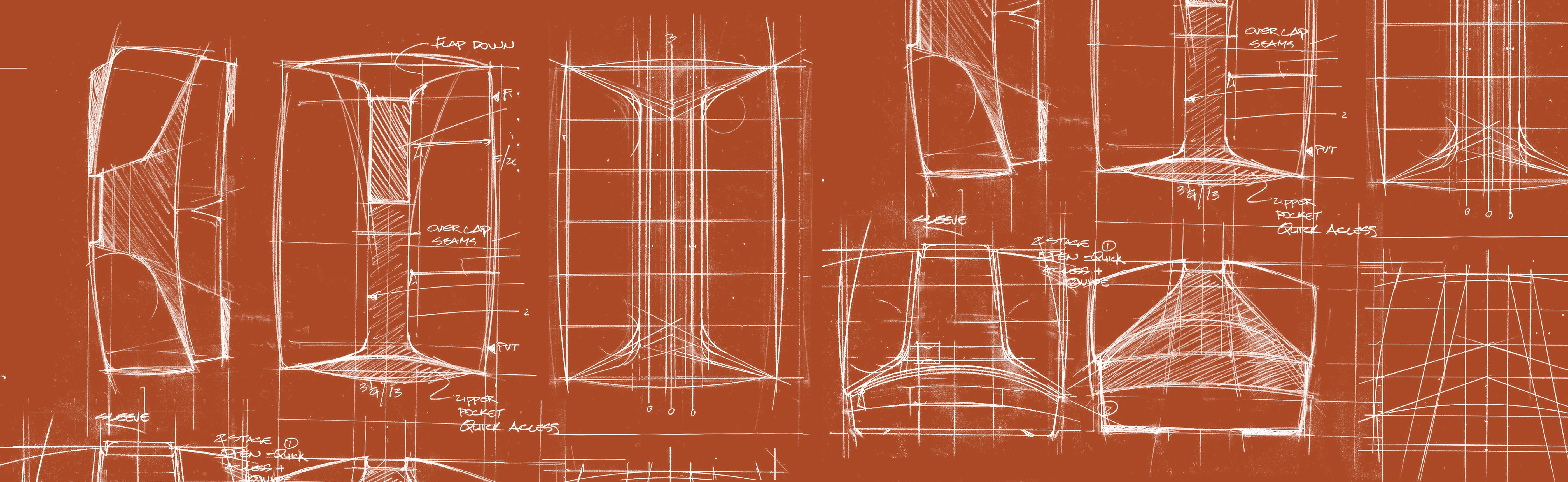

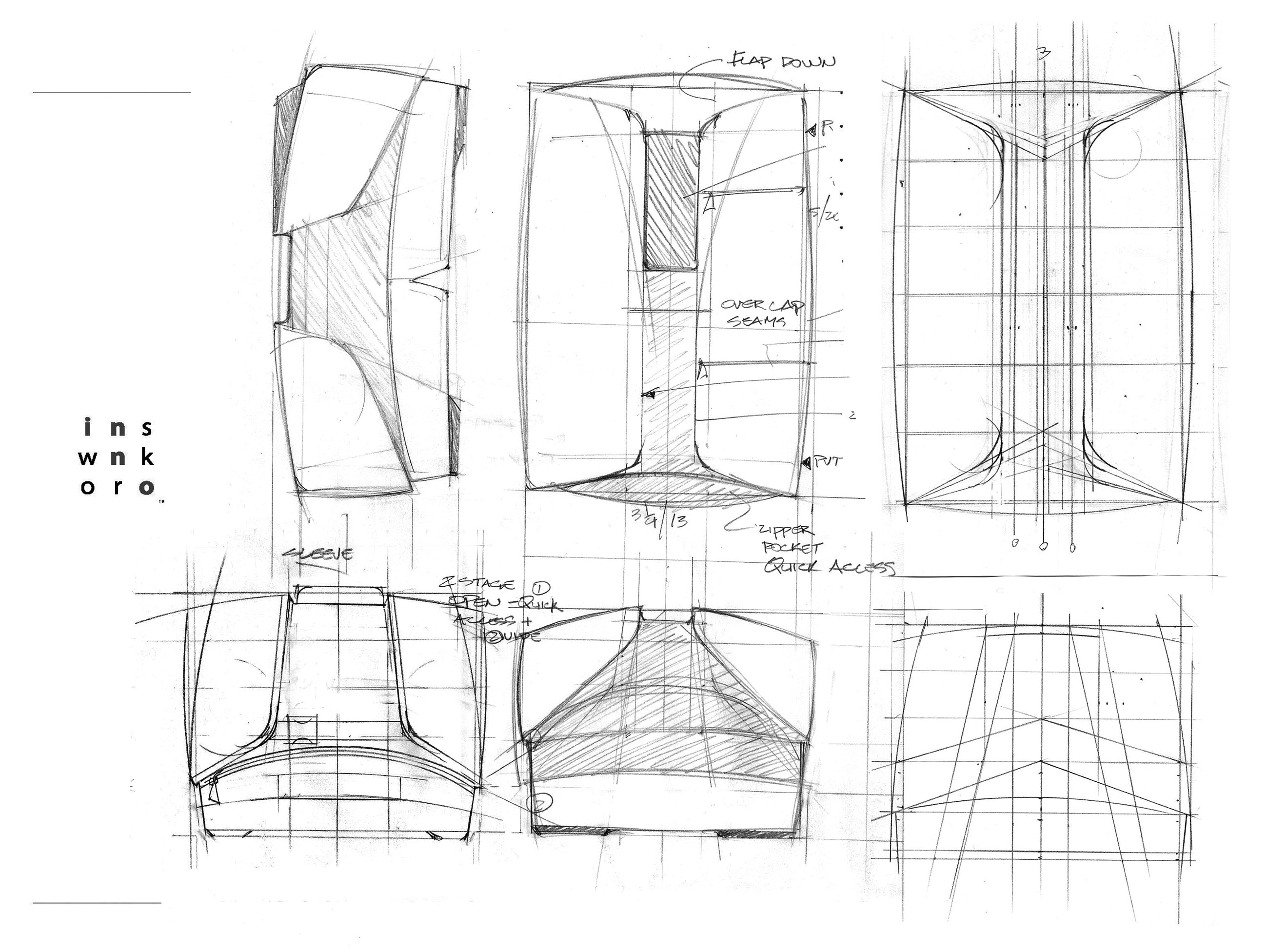

2 : Design

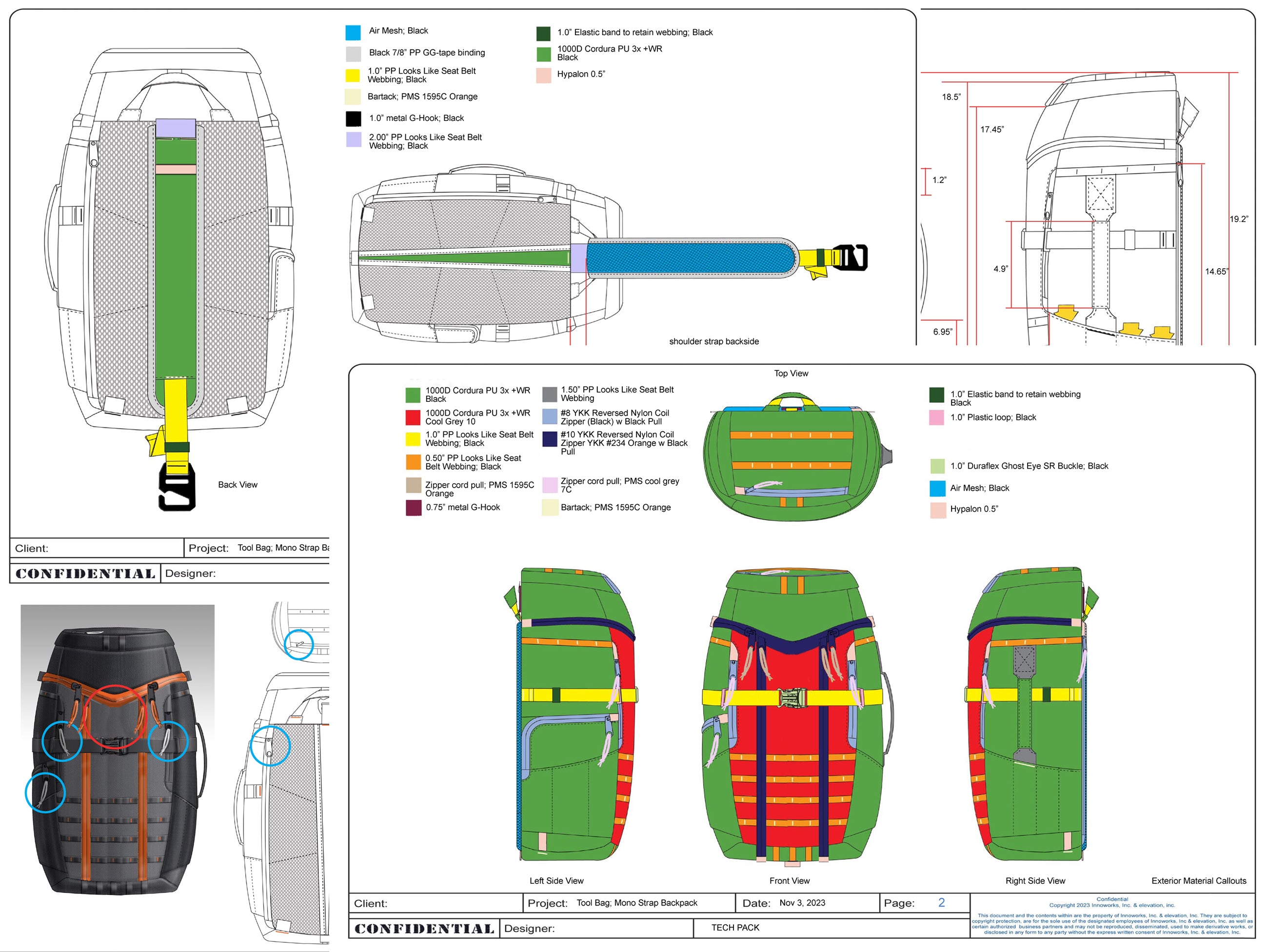

Continued development, evolution, and refinement of viable directions in 2D sketches, CG modeling & renderings, building simple 3D form studies; including of unique panel configuration, usability, ‘new’ tool storage organization configuration, and their effects on the chosen design directions.

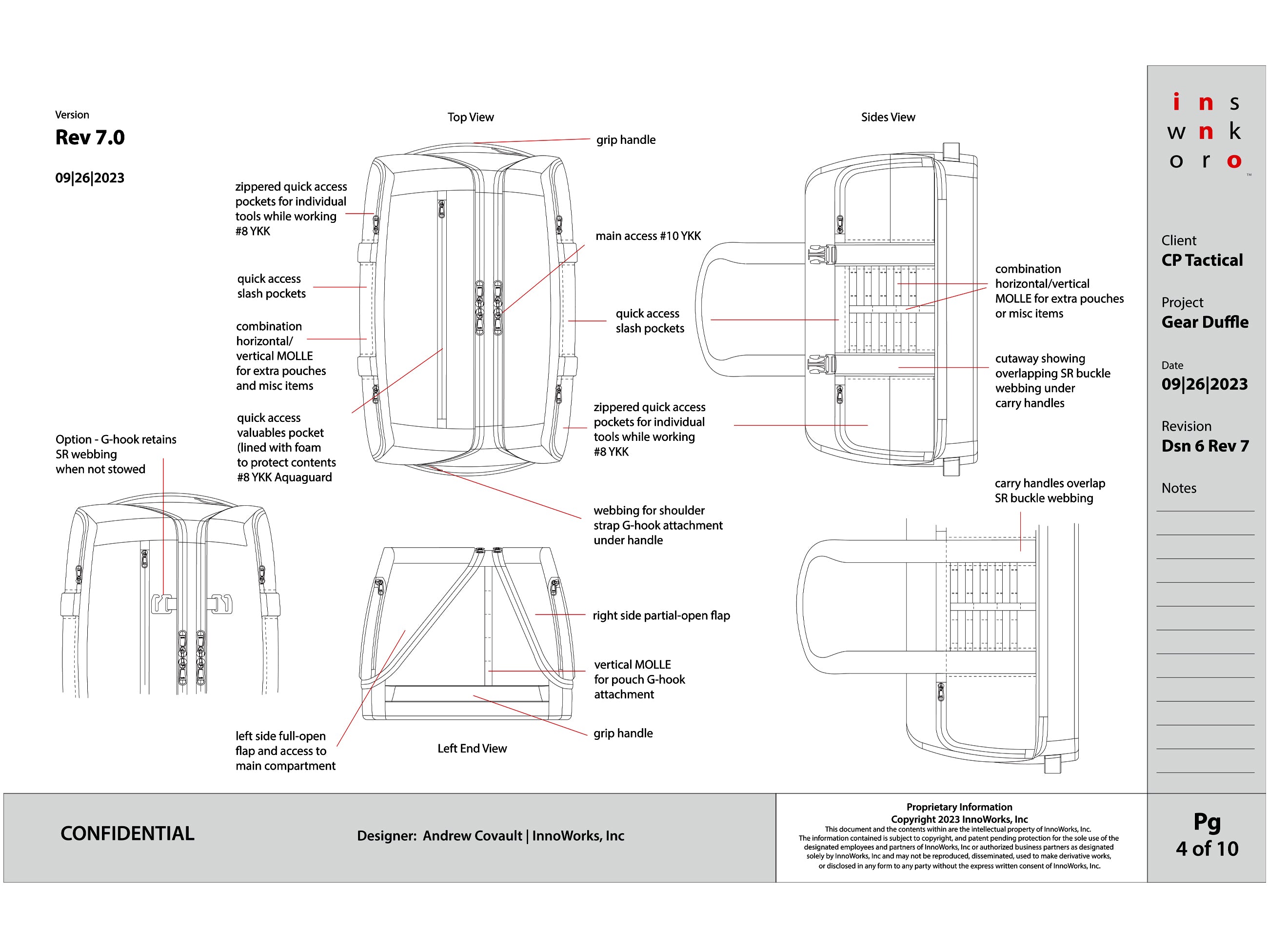

3 : Validate + Document

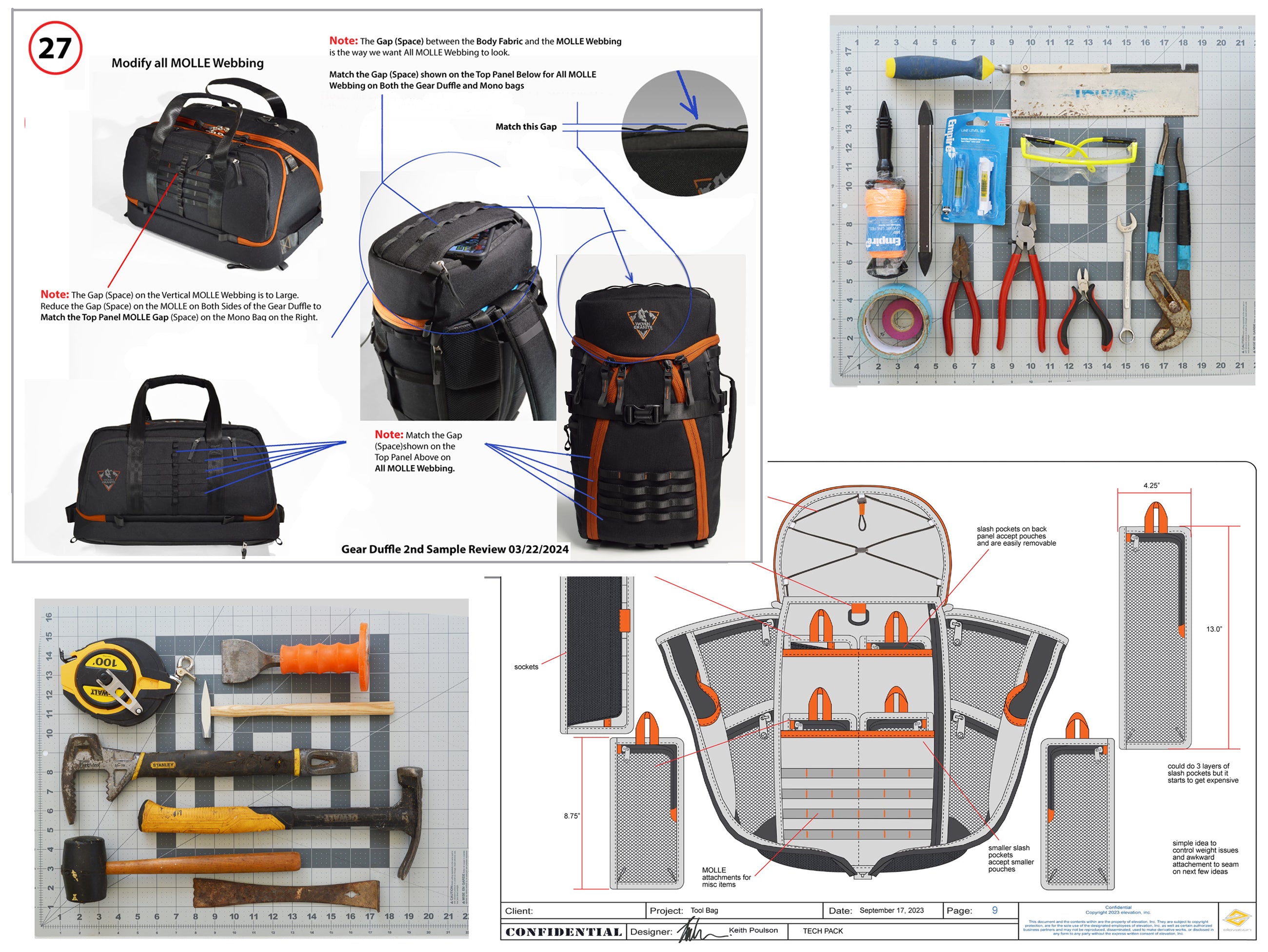

Refinement of chosen designs and the generation of comprehensive documentation in a series of Tech Pack documentation; defining all dimensions, panel construction options, sewing techniques for our Production Vendor Partner to create an iterative series of physical pre-production sample prototype versions for evaluation.

Once selected a final detailed specification Tech Pack for the creation of the ‘Golden Sample ‘ for production gear bags and accessory items are generated.

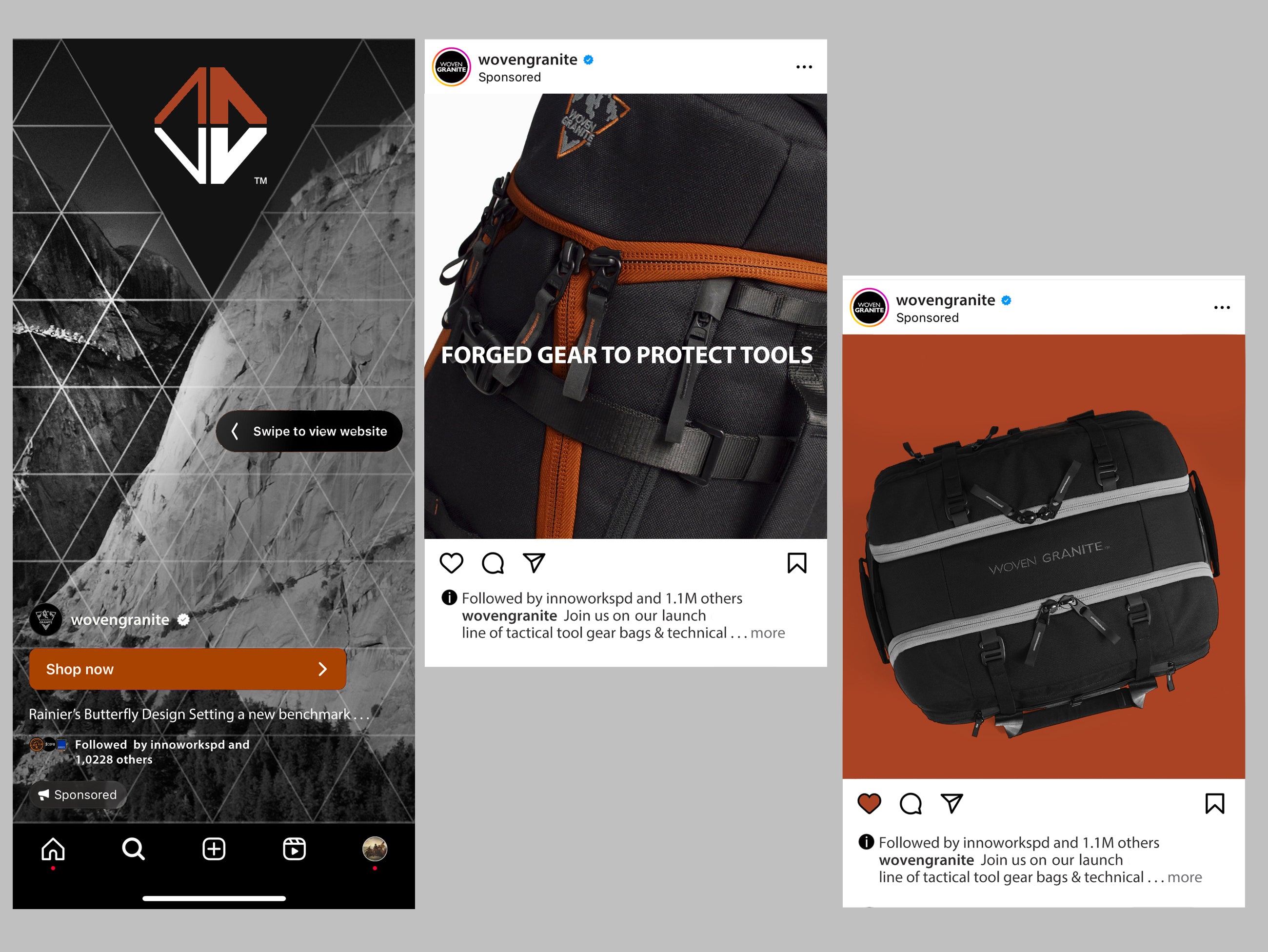

4 : Promotion

Development of our Intellectual Property to protect our trademarks and pending patents for the brand, build awareness on social media to; build our community, drive interest, and gain the financial backing needed to launch Woven Granite.

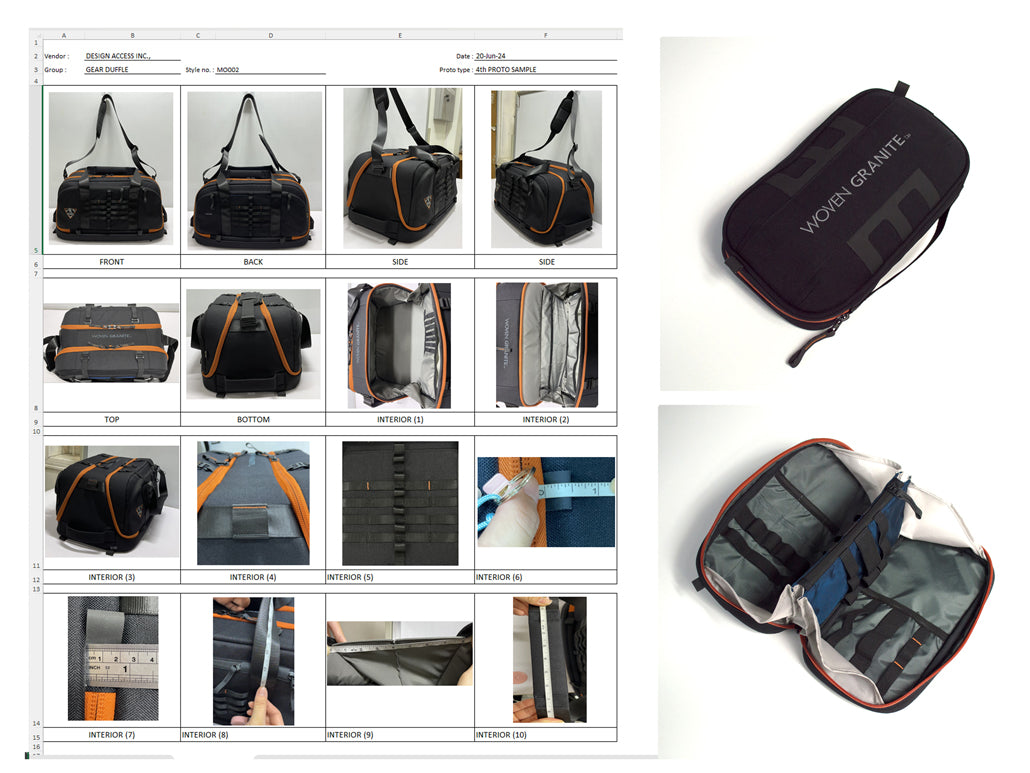

5 : Produce

February 20, 2024 - May 20, 2025

Covers any pre-production evaluation and refinements to all ‘Golden Sample Products’ with our Production Vendor Partner, Logistics Partner ensuring all detailing of the chosen product solution, and agreed upon project goals and deliverables are carried completely thru production to distribution.

Production begins with ‘First Article Production Sample’ that all produced goods will be judged against and established as Quality Control Article.

6 : Distribute

Multi step process of consumer ready products are individually packaged, protected, and boxed ready for shipment.

Our Logistics Partner takes possession from our Manufacture Vendor Partner in their country of origin and loaded on the container ship to be shipped to our US port in Los Angels, California.

Once the shipment clears customs in the US, all products are transported to Woven Granite's fulfillment center in Utah by train or by semitrailer. Items are sorted, catalogued, placed in our custom protective polybag in our warehouse, orders are reviewed, filled and delivered to our customers.

Email notice is sent to all customers that the items will arrive soon.