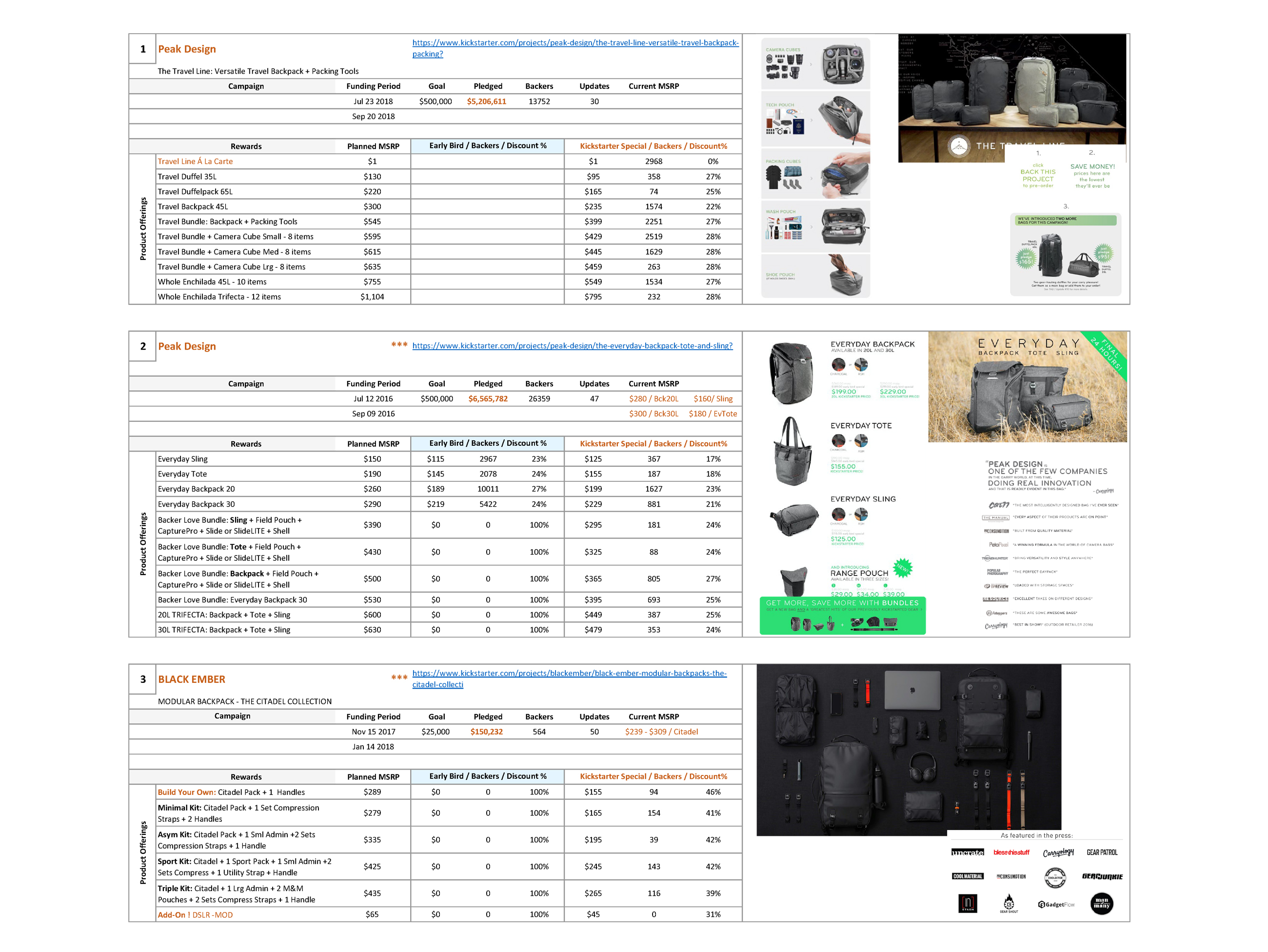

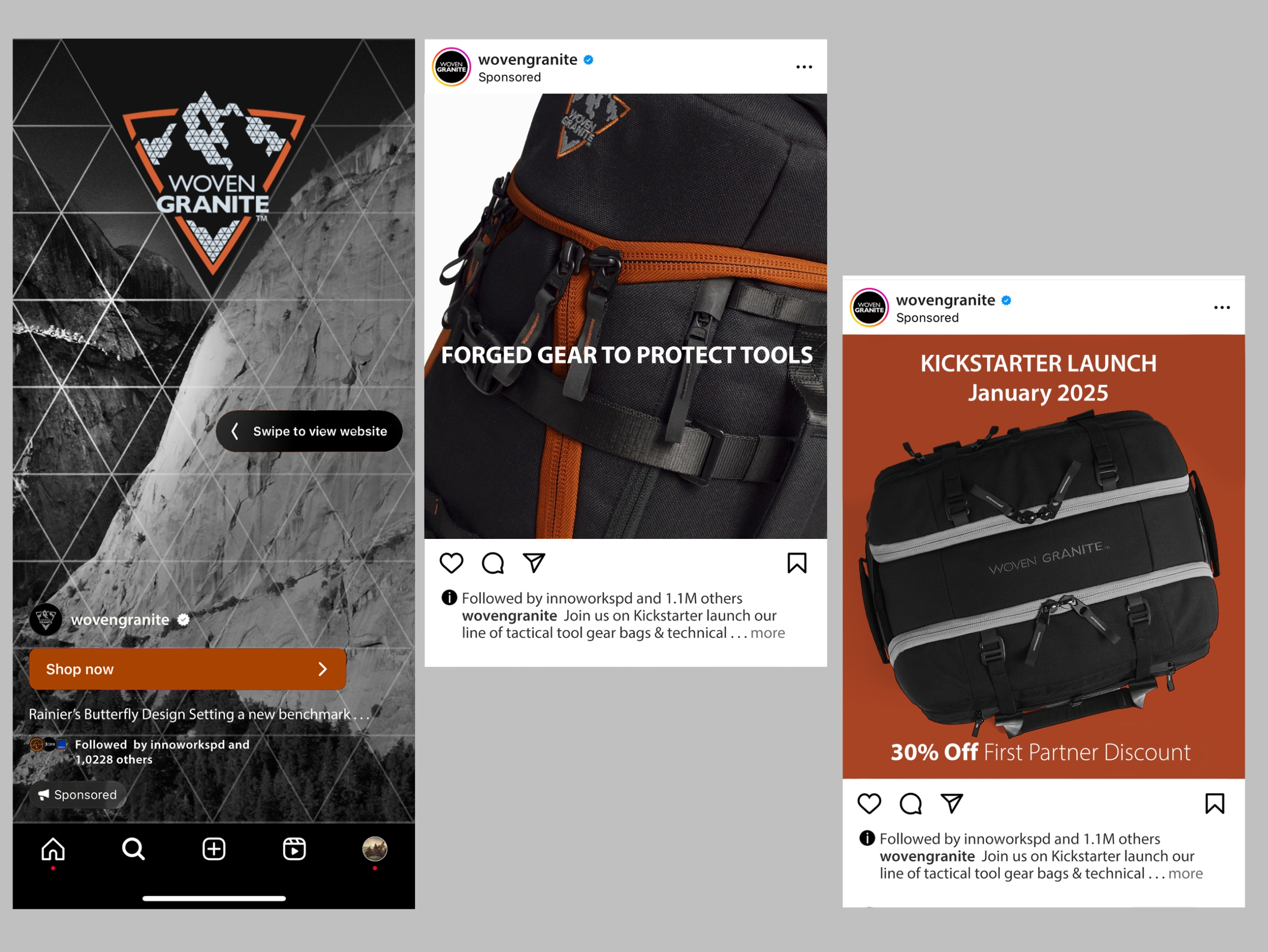

Benefits of a Kickstarter Launch?

Engagement. Connecting with early adopters is crucial for understanding what end users truly value in the tool gear category. Our Kickstarter launch, combined with active pre-launch social media outreach, invites potential customers to get to know the Woven Granite brand—its philosophy, and the compelling story of our founders, and their expertise. This dual approach not only serves as an effective marketing strategy but also helps us secure vital funding.

Insights. Our Kickstarter campaign and vibrant social media communities provide immediate, valuable, real-time feedback, allowing us to gather insights on our products and potential wish lists. We take this feedback seriously, integrating it into our market research to inform future designs while supporting our current product launches.

Autonomy. Crowdfunding platforms like Kickstarter empower us with the financial independence needed to operate without relying on external investment or venture capital. This freedom enables us to concentrate on delivering innovative products that meet customer needs, ultimately transforming our market segment and enhancing lives.